Inicio

Convocatoria asistente graduado docente doctoral

Convocatoria asistente graduado docente doctoralEl Departamento de Ingeniería Mecánica prevé la oportunidad a los estudiantes que se encuentren matriculados en el programa de Doctorado en Ingeniería...

Seminario de técnicas para algoritmos de optimización

Seminario de técnicas para algoritmos de optimizaciónDescubre cómo optimizar algoritmos con recursos limitados.

Los talleres de formación complementaria se ofertarán en el periodo intersemestral 2024

Los talleres de formación complementaria se ofertarán en el periodo intersemestral 2024Aprovechen esta oportunidad para ampliar sus conocimientos y habilidades durante el periodo intersemestral.

Uniandes y Coursera formarán Gerentes de Ingeniería

Uniandes y Coursera formarán Gerentes de Ingeniería¡Estamos emocionados de presentarte la nueva Maestría en Gerencia de la Ingeniería (MAGI) de Uniandes y Coursera! Aprende en modalidad virtual y en...

Convenios

ConveniosLa diversidad cultural y académica que se deriva de estas colaboraciones enriquece el ambiente de aprendizaje, fomentando la apertura mental, la...

El Consultorio IMEC

El Consultorio IMECTe invitamos a conocer y participar en este espacio abierto al público, orientado a trabajar con un equipo de consultores en formación.

Pregrado en Ingeniería Mecánica

Pregrado en Ingeniería MecánicaNuestro principal objetivo es generar soluciones con enfoque tecnológico en torno a problemáticas sociales o industriales, que permitan mejorar la...

Maestría en Ingeniería Mecánica

Maestría en Ingeniería MecánicaLos egresados del programa están preparados para liderar proyectos y áreas de innovación y desarrollo en organizaciones locales y globales, desarrollar...

ABET

ABETEl pregrado en Ingeniería Mecánica está acreditado por la Comisión de Acreditación de Ingeniería (EAC) de ABET. Conoce más de esta acreditación.

Noticias

21/02/2024Corriendo contra las probabilidadesEl Departamento de Ingeniería Mecánica de la Facultad de Ingeniería de la Universidad de los Andes se complace en invitarlos a la Charl...

21/02/2024Corriendo contra las probabilidadesEl Departamento de Ingeniería Mecánica de la Facultad de Ingeniería de la Universidad de los Andes se complace en invitarlos a la Charl... 29/01/2024Los talleres de formación complementaria se ofertarán...Nos complace informarles que durante el periodo intersemestral de 2024, se ofrecerán diversos talleres de formación complementaria para...

29/01/2024Los talleres de formación complementaria se ofertarán...Nos complace informarles que durante el periodo intersemestral de 2024, se ofrecerán diversos talleres de formación complementaria para... 08/11/2023Toyota y Asocaña presentarán la Corolla Cross XRX...Un primer modelo con el que se quiere mostrar que el bioetanol puede ser una estrategia de combustible sostenible En un emocionante...

08/11/2023Toyota y Asocaña presentarán la Corolla Cross XRX...Un primer modelo con el que se quiere mostrar que el bioetanol puede ser una estrategia de combustible sostenible En un emocionante... 24/10/2023Uniandes y Coursera formarán Gerentes de IngenieríaDesde marzo de 2024, la nueva Maestría en Gerencia de la Ingeniería formará en modalidad virtual y en español a profesionales...

24/10/2023Uniandes y Coursera formarán Gerentes de IngenieríaDesde marzo de 2024, la nueva Maestría en Gerencia de la Ingeniería formará en modalidad virtual y en español a profesionales... 18/09/2023Profesor Giacomo Barbieri en la PUCV de ChileEl Profesor Giacomo Barbieri fue invitado por la Pontificia Universidad Católica de Valparaíso (PUCV) en Chile para presentar dos confe...

18/09/2023Profesor Giacomo Barbieri en la PUCV de ChileEl Profesor Giacomo Barbieri fue invitado por la Pontificia Universidad Católica de Valparaíso (PUCV) en Chile para presentar dos confe... 13/09/2023Experto en Biomecatrónica y Robótica ingresa al...El Departamento de Ingeniería Mecánica se enorgullece en anunciar la incorporación del destacado experto en biomecatrónica, Jonathan Ca...

13/09/2023Experto en Biomecatrónica y Robótica ingresa al...El Departamento de Ingeniería Mecánica se enorgullece en anunciar la incorporación del destacado experto en biomecatrónica, Jonathan Ca... 06/09/2023Renuevan el nombramiento de Juan Pablo Casas en...La Rectoría aprobó la renovación del nombramiento de Juan Pablo Casas Rodríguez, como director del Departamento de Ingeniería Mecá...

06/09/2023Renuevan el nombramiento de Juan Pablo Casas en...La Rectoría aprobó la renovación del nombramiento de Juan Pablo Casas Rodríguez, como director del Departamento de Ingeniería Mecá... 10/08/2023Taller de Electrónica BásicaPLAN 2023-2 ELECTRÓNICA BÁSICA: Taller práctico en donde se familiarizará con conceptos básicos de electricidad y electrónica,...

10/08/2023Taller de Electrónica BásicaPLAN 2023-2 ELECTRÓNICA BÁSICA: Taller práctico en donde se familiarizará con conceptos básicos de electricidad y electrónica,... 18/07/2023Giacomo Barbieri y David Sánchez presentan artículos...Yokohama, Japón - El profesor Giacomo Barbieri, junto con el estudiante de doctorado David Sánchez Londoño, participaron en el 22º Cong...

18/07/2023Giacomo Barbieri y David Sánchez presentan artículos...Yokohama, Japón - El profesor Giacomo Barbieri, junto con el estudiante de doctorado David Sánchez Londoño, participaron en el 22º Cong... 08/06/2023Estudiantes exploran la gestión energética en EmpacorLos estudiantes de la clase de Gerencia de la Energía del Departamento de Ingeniería Mecánica de la Universidad de los Andes tuvieron u...

08/06/2023Estudiantes exploran la gestión energética en EmpacorLos estudiantes de la clase de Gerencia de la Energía del Departamento de Ingeniería Mecánica de la Universidad de los Andes tuvieron u... 07/06/2023Taller de formación técnica complementaria 2023-2INSCRIPCIONES: 7 de Junio a 16 de Junio Los talleres se realizarán entre el 20 de Junio y el 28 de Julio Talleres...

07/06/2023Taller de formación técnica complementaria 2023-2INSCRIPCIONES: 7 de Junio a 16 de Junio Los talleres se realizarán entre el 20 de Junio y el 28 de Julio Talleres... 02/06/2023Cambios en la política de retiro de cursos 2023-2A partir del 2023-2 se presentarán algunos cambios importantes en la política de retiros de cursos. Los estudiantes podrán retirar curs...

02/06/2023Cambios en la política de retiro de cursos 2023-2A partir del 2023-2 se presentarán algunos cambios importantes en la política de retiros de cursos. Los estudiantes podrán retirar curs... 25/05/2023Innovación y Soluciones del Mundo RealDescubre la Feria TRANSFORMA de Ingeniería Mecánica. El pasado miércoles 24 de mayo, nuestras instalaciones en la Calle del Saber se co...

25/05/2023Innovación y Soluciones del Mundo RealDescubre la Feria TRANSFORMA de Ingeniería Mecánica. El pasado miércoles 24 de mayo, nuestras instalaciones en la Calle del Saber se co... 19/05/2023Maestría en Ingeniería Mecánica: Admitidos 2023-1¡Felicitaciones a los admitidos a la Maestría en Ingeniería Mecánica 2023-1 de la Universidad de los Andes! Han abierto las puertas hac...

19/05/2023Maestría en Ingeniería Mecánica: Admitidos 2023-1¡Felicitaciones a los admitidos a la Maestría en Ingeniería Mecánica 2023-1 de la Universidad de los Andes! Han abierto las puertas hac... 11/05/2023Semana de la InnovaciónDel 15 al 19 de mayo de 2023 se llevará a cabo una nueva versión de la Semana de la Innovación, un evento organizado por la Universidad...

11/05/2023Semana de la InnovaciónDel 15 al 19 de mayo de 2023 se llevará a cabo una nueva versión de la Semana de la Innovación, un evento organizado por la Universidad... 10/05/2023¡Pongámonos la 10 por la acreditación!Desde nuestra universidad construimos país, investigamos, desarrollamos pensamiento crítico e impactamos a nuestra sociedad. Sigamos tr...

10/05/2023¡Pongámonos la 10 por la acreditación!Desde nuestra universidad construimos país, investigamos, desarrollamos pensamiento crítico e impactamos a nuestra sociedad. Sigamos tr...

Catálogo de materias IMEC

- Sistemas automatizadosCódigo: IMEC 2003 Este taller introduce el estudiante a los sistemas automatizados a través del uso e integración de sensores, actua...

- Conversión de EnergíaCódigo: IMEC 3345 El objetivo general de este curso es darle al estudiante una visión integral de los sistemas y equipos industriale...

- Aereodinámica BásicaCódigo: IMEC 3250 Este curso suministra herramientas de aplicación de la Mecánica de Fluidos en la Aerodinámica. Se espera que hacia...

- Taller de Profundización en Diseño GráficoCódigo: IMEC 2004 En este curso se aborda el dibujo de ingeniería como pilar en el proceso de diseño mecánico y como medio de comuni...

- Desarrollo de aplicaciones robotizadasCódigo: IMEC 3536 En este curso se desarrollan destrezas para la implantación de aplicaciones con el apoyo de manipuladores robótico...

- Mantenimiento IndustrialCódigo: IMEC 3506 A maintenance engineer is an engineer with a multidisciplinary background involving science, engineering, and tech...

- Introducción a la Programación de Robots IndustrialesCódigo: IMEC 2717 Este es un curso taller de 8 semanas donde se desarrollan destrezas para la programar aplicaciones con manipulador...

- Procesos de Manufactura IndustrialCódigo: IMEC 3461 Este curso busca introducir al estudiante en el entendimiento de métodos tecnológicos comunes involucrados en la m...

- Dinámica AvanzadaCódigo: IMEC 4503 En este curso se presentan métodos modernos de modelamiento de sistemas dinámicos en tres dimensiones, adecuados p...

- Gerencia de la energíaCódigo: IMEC 3351 Con el objetivo de sensibilizar sobre la importancia del adecuado y oportuno manejo de los recursos energéticos, e...

- P2 Proyecto IntermedioCódigo: IMEC 2700 El curso Proyecto Intermedio es el segundo curso de la serie de cuatro cursos basados en proyectos que hacen parte...

- Mediciones de variables físicasCódigo: IMEC 2002 En este taller el estudiante aprende a medir las principales variables que interactúan dentro de la práctica de la...

- Proyecto IndividualCódigo: IMEC 3711 Es un trabajo autónomo dirigido y desarrollado por estudiantes de último año enmarcado en una de las modalidades p...

- Ingeniería básica de MotocicletasCódigo: IMEC 3504 En este curso se presentan los sistemas mecánicos que componen una motocicleta analizando su operación normal, sit...

- Herramientas CADCódigo: IMEC 2005 En este curso se aborda el diseño asistido por computador (CAD por sus siglas en inglés) como una herramienta indi...

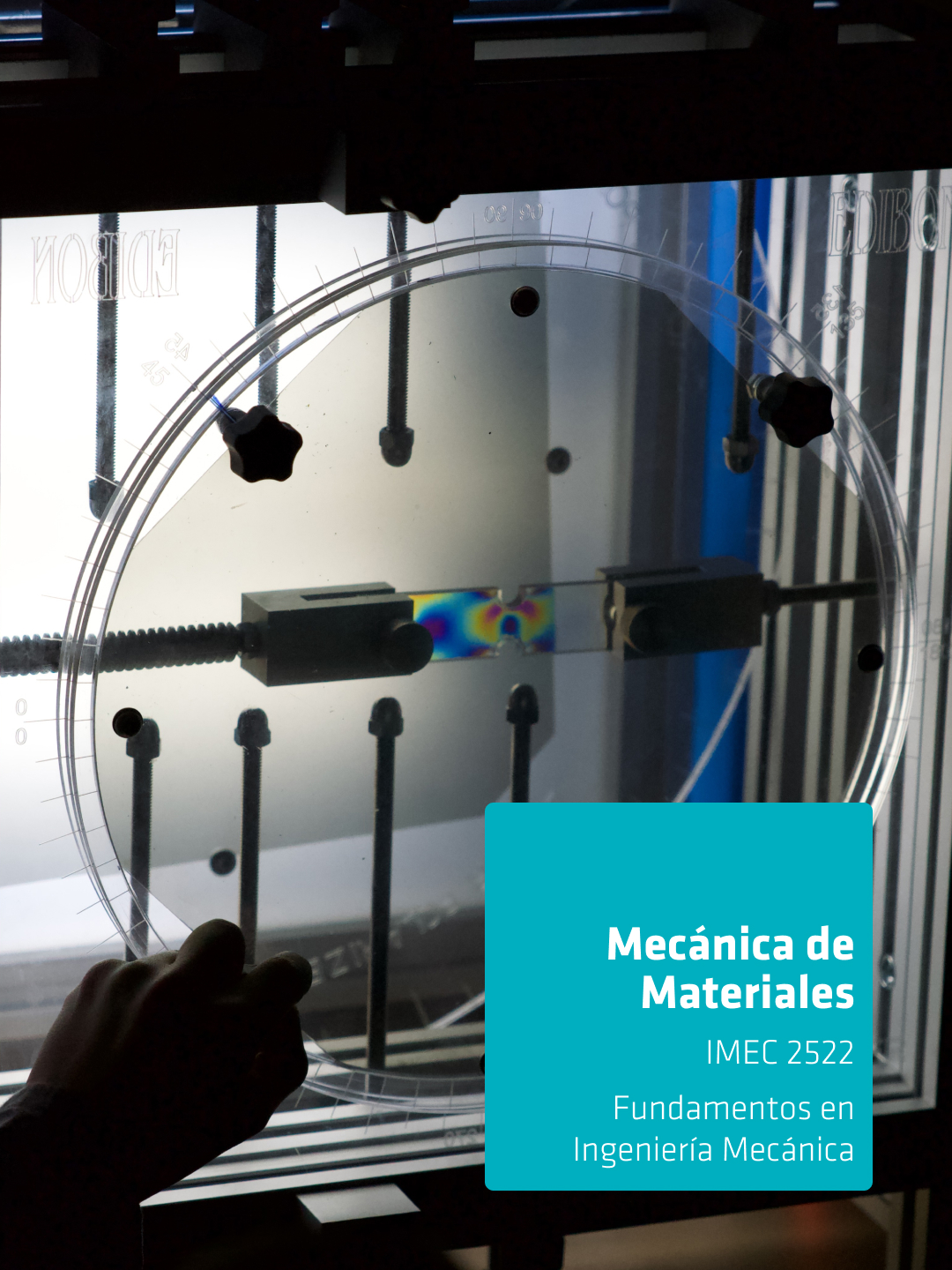

- Mecánica de MaterialesCódigo: IMEC 2522 Uno de los problemas más comunes para un ingeniero es decidir las dimensiones, la forma y los materiales de un ele...

Multimedia

eventos realizados

Desafíos y realidades de la movilidad eléctricaFecha:24 de Mayo del 2023Lugar: Universidad de los Andes

Desafíos y realidades de la movilidad eléctricaFecha:24 de Mayo del 2023Lugar: Universidad de los Andes Doctorado en Alemania: metas, desafíos y logrosFecha:11 de Mayo del 2023Lugar: Evento virtual

Doctorado en Alemania: metas, desafíos y logrosFecha:11 de Mayo del 2023Lugar: Evento virtual 1er Congreso de Energía y Transición EnergéticaFecha:De 04 de Mayo del 2023 hasta 05 de Mayo del 2023Lugar: Universidad de los Andes

1er Congreso de Energía y Transición EnergéticaFecha:De 04 de Mayo del 2023 hasta 05 de Mayo del 2023Lugar: Universidad de los Andes Sin miedo a volar: emprendiendo dentro de la industria tradicional...Fecha:16 de Marzo del 2023Lugar: Evento virtual

Sin miedo a volar: emprendiendo dentro de la industria tradicional...Fecha:16 de Marzo del 2023Lugar: Evento virtual MATLAB y Python para Inteligencia ArtificialFecha:15 de Marzo del 2023Lugar: Auditorio Mario Laserna C

MATLAB y Python para Inteligencia ArtificialFecha:15 de Marzo del 2023Lugar: Auditorio Mario Laserna C Ponte Pilas con la Calidad | PregradoFecha:De 16 de Agosto del 2022 hasta 25 de Agosto del 2022Lugar: Universidad de los Andes

Ponte Pilas con la Calidad | PregradoFecha:De 16 de Agosto del 2022 hasta 25 de Agosto del 2022Lugar: Universidad de los Andes Microplastic - Formation and DegradationFecha:14 de Julio del 2022Lugar: Universidad de los Andes

Microplastic - Formation and DegradationFecha:14 de Julio del 2022Lugar: Universidad de los Andes Desarrollo y Certificación de Sistemas de Control Automático en la...Fecha:13 de Julio del 2022Lugar: Zoom

Desarrollo y Certificación de Sistemas de Control Automático en la...Fecha:13 de Julio del 2022Lugar: Zoom Solid-state welding and processing of engineering materials:...Fecha:28 de Junio del 2022Lugar: Salón ML 514

Solid-state welding and processing of engineering materials:...Fecha:28 de Junio del 2022Lugar: Salón ML 514 Vidrios blindados: herramientas para el diseño y validaciónFecha:26 de Mayo del 2022Lugar: Zoom

Vidrios blindados: herramientas para el diseño y validaciónFecha:26 de Mayo del 2022Lugar: Zoom Transforma: Feria de proyectos 2022-1Fecha:De 26 de Mayo del 2022 hasta 07 de Junio del 2022Lugar: Calle del saber ML y Sala de aprendizaje interactivo ML

Transforma: Feria de proyectos 2022-1Fecha:De 26 de Mayo del 2022 hasta 07 de Junio del 2022Lugar: Calle del saber ML y Sala de aprendizaje interactivo ML Panel: ¿Cómo impacta a Colombia el conflicto entre Rusia y Ucrania?Fecha:19 de Mayo del 2022Lugar: LL_001

Panel: ¿Cómo impacta a Colombia el conflicto entre Rusia y Ucrania?Fecha:19 de Mayo del 2022Lugar: LL_001 La Ingeniería Mecánica en la industria automotriz del hoyFecha:17 de Mayo del 2022Lugar: Zoom

La Ingeniería Mecánica en la industria automotriz del hoyFecha:17 de Mayo del 2022Lugar: Zoom Lower-Limb Assistive Devices Informed by Human Biomechanical ModelsFecha:03 de Mayo del 2022Lugar: Zoom

Lower-Limb Assistive Devices Informed by Human Biomechanical ModelsFecha:03 de Mayo del 2022Lugar: Zoom Biomedical Engineering: Implant Development and Surface EngineeringFecha:27 de Abril del 2022Lugar: Salón ML 607

Biomedical Engineering: Implant Development and Surface EngineeringFecha:27 de Abril del 2022Lugar: Salón ML 607 Malta University, Cultural Heritage Protection and Materials...Fecha:26 de Abril del 2022Lugar: Salón B-202

Malta University, Cultural Heritage Protection and Materials...Fecha:26 de Abril del 2022Lugar: Salón B-202 Modelos de Orden Reducido para la simulación de flujos inestablesFecha:31 de Marzo del 2022Lugar: Zoom

Modelos de Orden Reducido para la simulación de flujos inestablesFecha:31 de Marzo del 2022Lugar: Zoom La Ingeniería Mecánica en la practicidad de la vidaFecha:08 de Marzo del 2022Lugar: Plataforma Zoom

La Ingeniería Mecánica en la practicidad de la vidaFecha:08 de Marzo del 2022Lugar: Plataforma Zoom Ingeniería mecánica en el desarrollo de la energía solarFecha:16 de Febrero del 2022Lugar: Salón RGD 210 o plataforma Zoom

Ingeniería mecánica en el desarrollo de la energía solarFecha:16 de Febrero del 2022Lugar: Salón RGD 210 o plataforma Zoom Granta Edupack "Space Exploration: Materials for Rocket Tanks...Fecha:15 de Diciembre del 2021Lugar:

Granta Edupack "Space Exploration: Materials for Rocket Tanks...Fecha:15 de Diciembre del 2021Lugar: Transforma: Feria de proyectos 2021-2Fecha:De 13 de Diciembre del 2021 hasta 15 de Diciembre del 2021Lugar: Zoom

Transforma: Feria de proyectos 2021-2Fecha:De 13 de Diciembre del 2021 hasta 15 de Diciembre del 2021Lugar: Zoom El Rol de la Dinámica de Fluidos Computacional en el Diseño y...Fecha:23 de Noviembre del 2021Lugar: Zoom

El Rol de la Dinámica de Fluidos Computacional en el Diseño y...Fecha:23 de Noviembre del 2021Lugar: Zoom Foro Sociedad 5.0: Aplicación integrada de soluciones basadas en...Fecha:19 de Noviembre del 2021Lugar: Virtual

Foro Sociedad 5.0: Aplicación integrada de soluciones basadas en...Fecha:19 de Noviembre del 2021Lugar: Virtual Seminario Modelo de gestión del mantenimiento y confiabilidad...Fecha:13 de Noviembre del 2021Lugar: Zoom

Seminario Modelo de gestión del mantenimiento y confiabilidad...Fecha:13 de Noviembre del 2021Lugar: Zoom Webinar: Biocombustibles obtenidos vía conversión térmica de...Fecha:04 de Noviembre del 2021Lugar: Zoom

Webinar: Biocombustibles obtenidos vía conversión térmica de...Fecha:04 de Noviembre del 2021Lugar: Zoom Modelo analítico del ensayo para fatiga en tuberías mediante el...Fecha:21 de Octubre del 2021Lugar: Zoom

Modelo analítico del ensayo para fatiga en tuberías mediante el...Fecha:21 de Octubre del 2021Lugar: Zoom La democratización de diseño y nuevos paradigmas para la...Fecha:21 de Octubre del 2021Lugar: Zoom

La democratización de diseño y nuevos paradigmas para la...Fecha:21 de Octubre del 2021Lugar: Zoom Un laboratorio de agricultura en ambiente controlado en UniandesFecha:23 de Septiembre del 2021Lugar: Zoom

Un laboratorio de agricultura en ambiente controlado en UniandesFecha:23 de Septiembre del 2021Lugar: Zoom Celdas de combustible y de electrólisis para la producción de...Fecha:21 de Septiembre del 2021Lugar: Zoom

Celdas de combustible y de electrólisis para la producción de...Fecha:21 de Septiembre del 2021Lugar: Zoom Diseño de sistemas mecánicos para la transformación digitalFecha:25 de Agosto del 2021Lugar: Zoom

Diseño de sistemas mecánicos para la transformación digitalFecha:25 de Agosto del 2021Lugar: Zoom Desarrollo e innovación en vidrios de alta tecnología para los...Fecha:22 de Mayo del 2021Lugar: Zoom

Desarrollo e innovación en vidrios de alta tecnología para los...Fecha:22 de Mayo del 2021Lugar: Zoom