Nuestros Laboratorios

Nuestros laboratorios se encuentran ubicados en el Edifico Mario Laserna, contamos en total con 15 espacios destinados a labores académicas, de investigación y de servicios al sector industrial y externo.

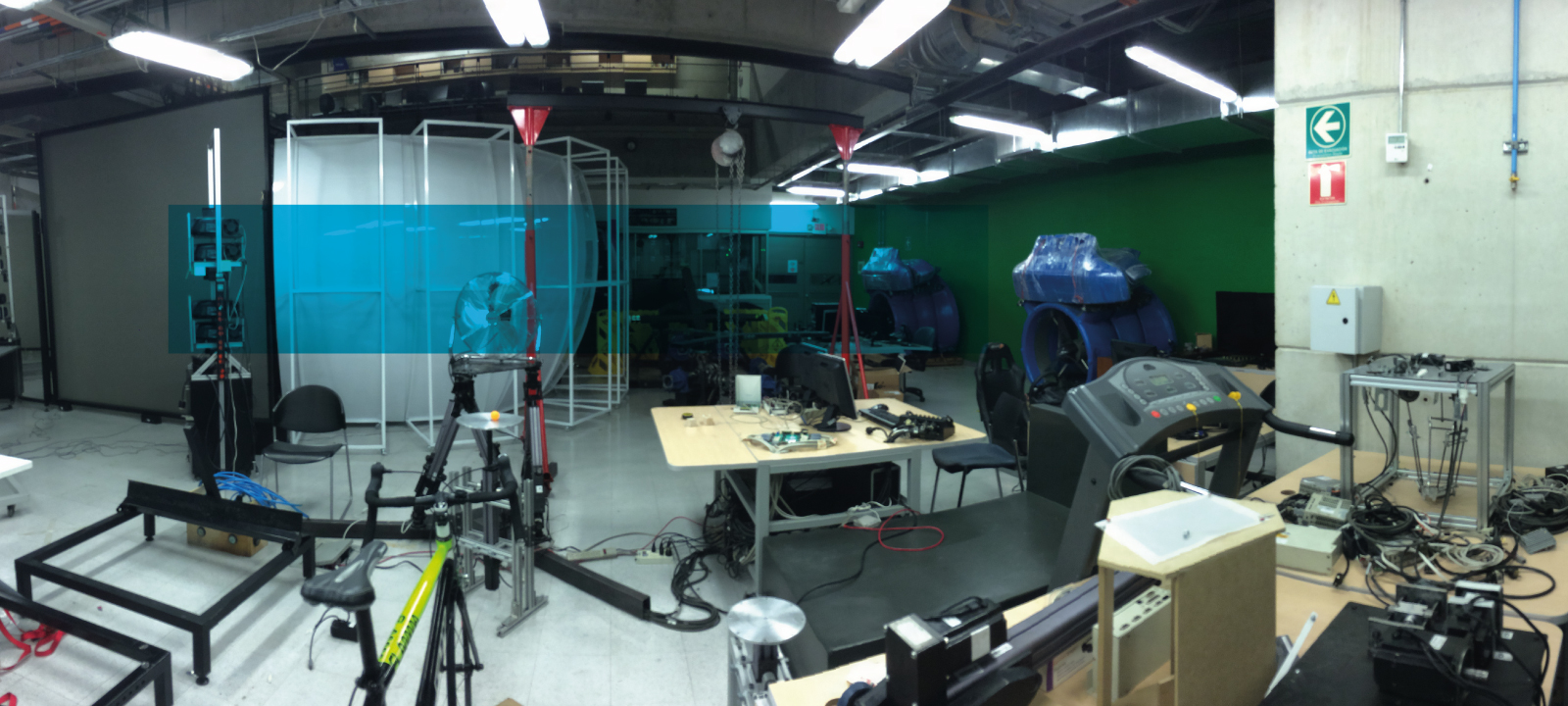

Este laboratorio reúne a investigadores relacionados con los temas de visualización inmersiva, realidad virtual, interfaces hombre máquina, procesamiento de imágenes, robótica y control.

Profesores y estudiantes de todos los niveles (doctorado, maestría y pregrado) de Ingeniería Mecánica, Ingeniería de Sistemas y Computación, Ingeniería Eléctrica y Electrónica, de Diseño y de Arte, colaboran alrededor de proyectos de alta tecnología con aplicaciones en Medicina, diseño, toma de decisiones, entretenimiento, entrenamiento, y tele-colaboración.

En un espacio especialmente diseñado para la experimentación en estas disciplinas, cuenta con 250 metros cuadrados, una altura de 8 metros y un conjunto de equipos de última generación en conectividad, computación, visualización, robótica e interacción. Es la primera instalación en su género en Colombia, competitiva a nivel internacional.

El objetivo de este laboratorio es el desarrollo y caracterización de prototipos de sistemas vehiculares. Este laboratorio se enfoca en desarrollo y la caracterización de vehículos terrestres sobre ruedas, así como de sus sub-sistemas. Estos sistemas se estudian con un enfoque multi-criterio, cubriendo diversas características de su funcionamiento, como su respuesta dinámica, sus características energéticas, entre otros.

El objetivo de este laboratorio es la caracterización de materiales a altas tasas de deformación, principalmente compuestos. Dentro de los proyectos realizados se encuentran caracterización de materiales balísticos, espumas rígidas y compuestos de fibras naturales.

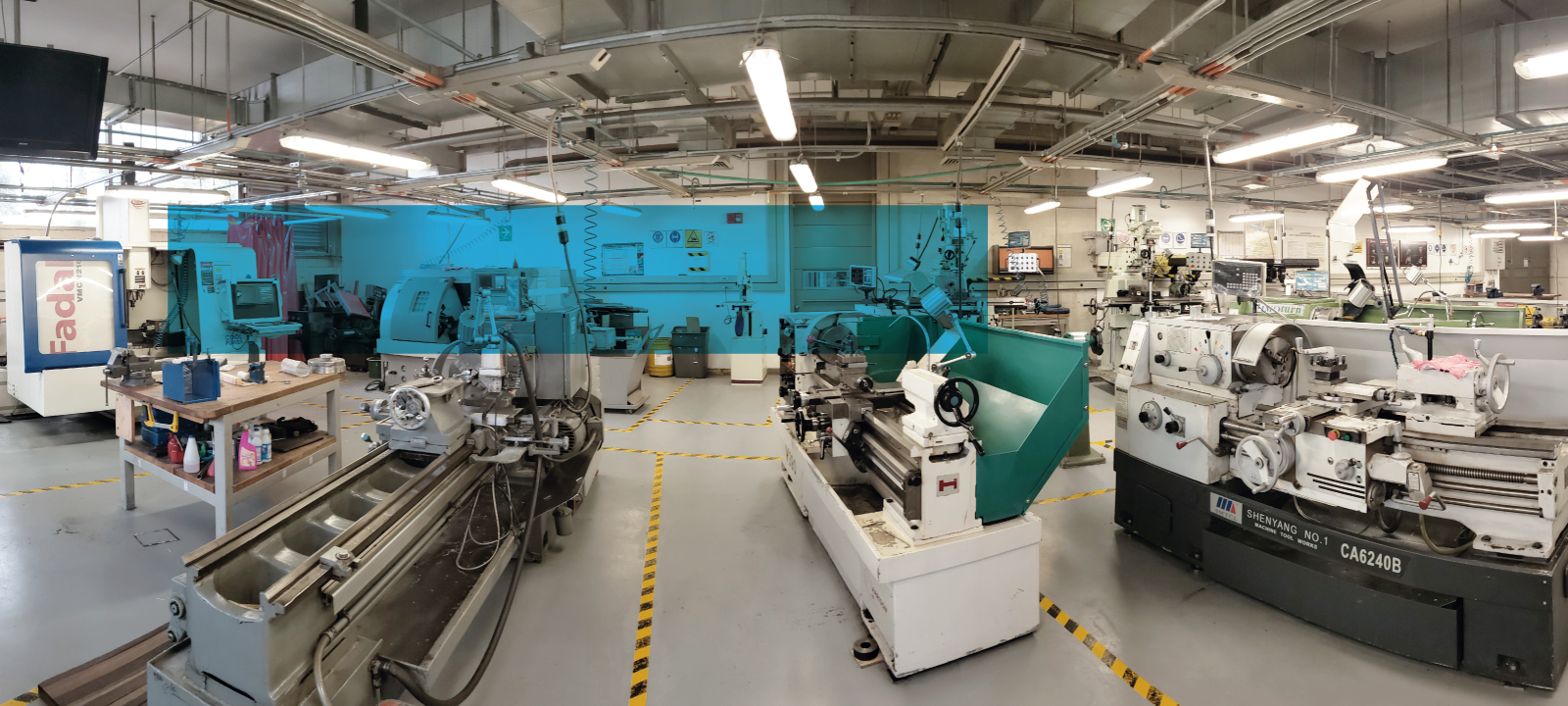

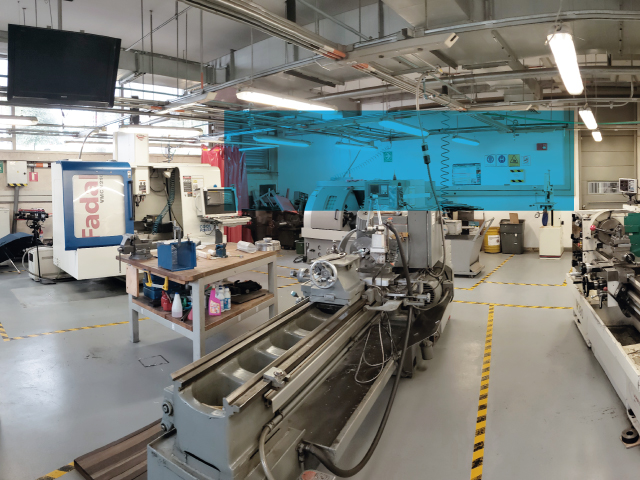

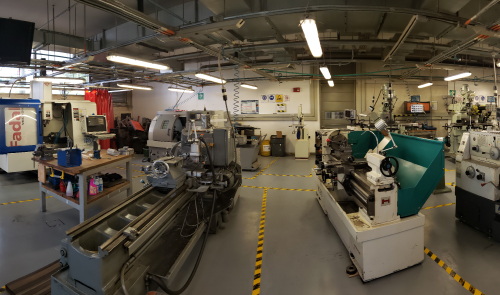

Este laboratorio está dotado con máquinas herramientas convencionales y CNC permitiendo la fabricación de piezas individuales, series cortas o sistemas complejos. Está dividido en varias secciones, la primera de ellas es el área de soldadura, donde se cuenta con equipos especializados para esta operación, la segunda contempla la zona de los bancos de trabajo donde se pueden hacer ensambles y operaciones con herramientas manuales, la tercera es un almacén de herramientas donde contamos con todo lo necesario para que los estudiantes desarrollen las actividades, la cuarta es el área de las máquinas donde se realizan los procesos de fresado, torneado y corte, y por último se cuenta con un espacio especializado para prototipado rápido con impresoras 3D tipo FDM y estereolitografía.

Consulte el reglamento de seguridad del Laboratorio de Manufactura ML-027.

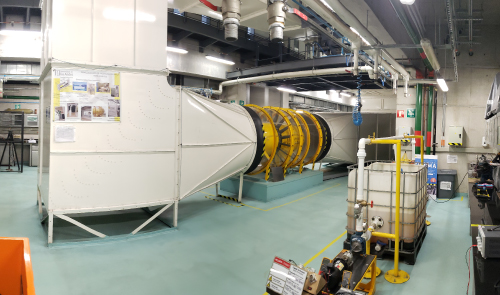

El Laboratorio de Dinámica de Fluidos ha sido concebido para ilustrar los principios físicos que hacen del movimiento y transporte de los fluidos un campo de investigación de la Ingeniería, y en especial de la Ingeniería Mecánica. Este espacio está desarrollado para acercar a los estudiantes a los diferentes fenómenos y principios de la Mecánica de Fluidos (hidráulicos y aerodinámicos), que se presentan cuando se transporta, mide y controla un fluido determinado.

La investigación se ocupa de los temas fundamentales, así como de estudios especiales para la industria, integrando las últimas herramientas de Diseño y Manufactura Asistidas por Computador (CAD/CAM, por sus siglas en inglés), Dinámica de Fluidos Computacional (CFD por sus siglas en inglés), con los diseños y prototipos desarrollados en el laboratorio.

Consulte el reglamento de seguridad del Laboratorio de Dinámica de Fluidos ML-032.

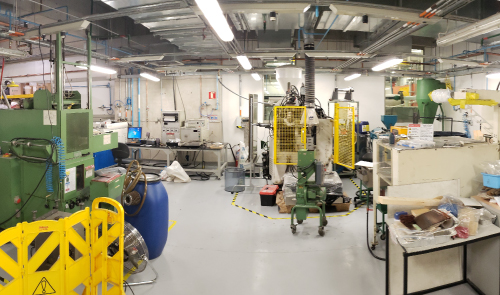

Este laboratorio le permitirá reproducir a una menor escala, los procesos reales que se presentan en la industria de la transformación de plástico. Tiene como objetivo académico, la pedagogía de procesos típicos de la industria, en la que se fabrican productos finales tales como bolsas, vasos, etc. Para lograr este propósito el laboratorio cuenta con una serie de equipos como extrusoras, termo-formadoras, sopladoras, inyectoras y moldes. Adicionalmente el laboratorio cuenta con una máquina de ensayos a fatiga, una máquina para fatiga por impacto, una “Drop weigth impact test” utilizadas para la caracterización dinámica de materiales de metálicos, compuestos y poliméricos.

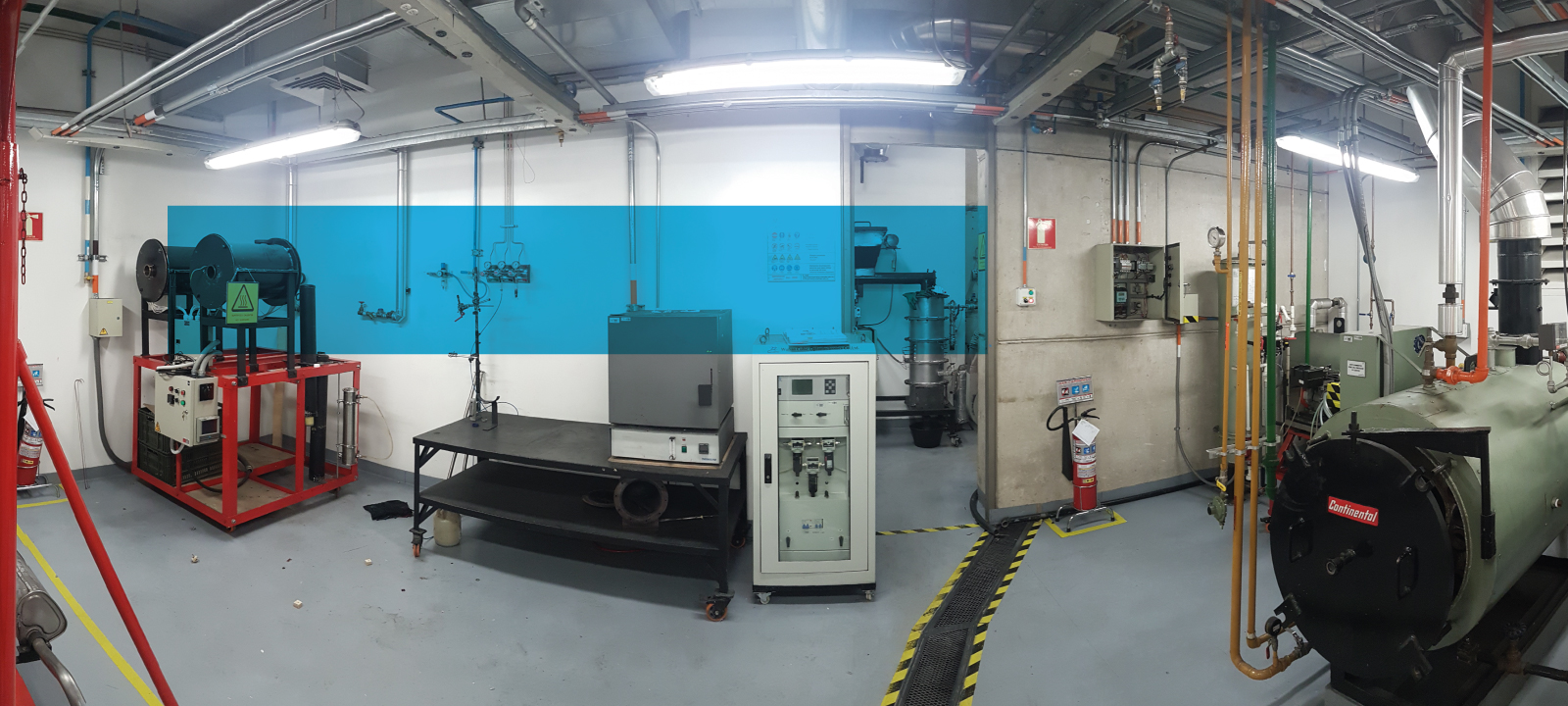

Nuestro laboratorio destinado para la enseñanza e investigación en el campo de las ciencias térmicas (Termodinámica, Transferencia de Calor y Combustión) nos permite aproximar a los estudiantes, mediante la experimentación, a los diversos fenómenos y procesos térmicos aplicados al uso de sistemas de conversión de energía y al desarrollo de proyectos de innovación energética, integrando nuevas tecnologías, y, a su vez, los conceptos relacionados con el uso eficiente de la energía mientras se minimiza su impacto ambiental.

Consulte el reglamento de seguridad del Laboratorio de Conversión de Energía ML-041.

Este laboratorio cuenta con la infraestructura para desarrollar métodos de caracterización de termoplásticos, elastómeros, compuestos y empaques para alimentos. Dentro de las técnicas más destacadas se cuentan con equipos para hacer análisis por infrarrojo FTIR, análisis dinámico mecánica DMA desde -130 °C hasta 600°C, cámara de envejecimiento por rayos UV, cámara para temperatura y humedad controlada, calorímetro diferencial de barrido DSC y un equipo para obtener la conductancia en polímeros.

Este laboratorio, cuenta con los equipos necesarios para la preparación y ataque de muestras metálicas y cerámicas, para su posterior análisis micro estructural.

Consulte el reglamento de seguridad del Laboratorio de Metalografía ML-205.

Este laboratorio tiene como finalidad, la investigación y el desarrollo en el campo de las tecnologías del plasma, la metalurgia de polvos y aplicaciones de ingeniería de los materiales cerámicos.

Consulte el reglamento de seguridad del Laboratorio de Polvos Metálicos y Cerámicos ML-209.

El laboratorio está dotado con tutores y equipos para estudiar el comportamiento de los materiales cuando están sometidos a cargas diversas, cuenta con un sistema de fotoelasticidad que permite medir esfuerzos y deformaciones en materiales transparentes, isotrópicos y continuos y t. El sistema permite visualizar en la pieza un contorno de colores que permite observar la intensidad de esfuerzos presentes, similar a los contornos de colores obtenidos al realizar un análisis por elementos finitos. A su vez, el laboratorio cuenta con un sistema portátil de detección de defectos por ultrasonido, el cual se utiliza para realizar estudios, y evaluar la integridad estructural de soldaduras, tuberías y ensambles en general.

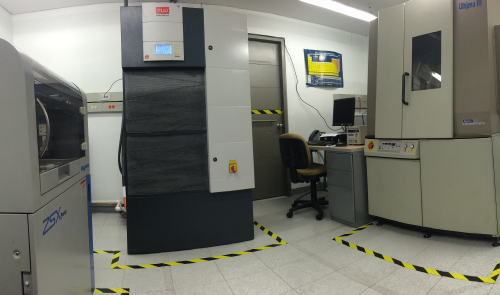

El laboratorio está dotado con equipos especializados para el análisis elemental y de fases cristalina de materiales metálicos y cerámicos principalmente. Cuenta con un Difractómetro de Rayos X que puede ser configurado para trabajar como Difractómetro de polvos en geometrías Bragg Brentano y Haz Paralelo, y con dos Espectrómetros uno de Fluorescencia de Rayos X por longitud de onda dispersiva (WDXRF) y un Espectrómetro de Emisión Óptica por chispa (OES).

El laboratorio de Difracción de Rayos–X y Espectroscopia, presta sus servicios a toda la Comunidad académica, investigativa y productiva dentro y fuera de la Universidad de los Andes.

Este laboratorio es utilizado para el análisis de imágenes aumentadas hasta 1000 x. Cuanta con un estereoscopio y varios microscopios que prestan servicio a procesos de análisis de falla y análisis general de superficies de elementos utilizados en la industria. Adicionalmente el laboratorio está dotado con durómetros y micro durómetros de diferentes escalas, que nos permiten completar los ensayos de caracterización de materiales realizados en los diversos laboratorios del departamento.

Consulte el reglamento de seguridad del Laboratorio de Microscopía Óptica ML-226.

En este laboratorio se encuentran tres máquinas de ensayos universales cada una con un rango de operación diferente que van desde 30 KN hasta 300 KN, para la obtención de propiedades mecánicas en la mayoría de materiales. Adicionalmente, se cuenta con una cámara térmica acoplada a una de las máquinas universales, permitiéndonos aumentar la temperatura de ensayo de las probetas hasta 300 grados centígrados. También está dotado con equipos especializados para el análisis de láminas y películas poliméricas. Es uno de los dos espacios que cuenta con condiciones de temperatura y humedad controlada.

Consulte el reglamento de seguridad del Laboratorio de Propiedades Mecánicas ML- 227.

Este laboratorio tiene como finalidad el desarrollo de actividades académicas e investigativas enmarcadas en la comprensión de métodos numéricos y computacionales, para el modelado y simulación de sistemas de interés en la ingeniería y las ciencias. La sala fue diseñada y concebida como un espacio colaborativo entre Ingeniería Industrial, Ingeniería Química, Geociencias Ingeniería de Petróleos e Ingeniería Mecánica.

El Laboratorio de Agricultura en Ambiente Controlado (18m2) tiene el objetivo de aportar a la generación de recomendaciones tecnológicas de hidroponía de cultivo sin suelo bajo condiciones protegidas. El laboratorio constituye un banco de pruebas para el desarrollo de metodologías experimentales que a través de su escalamiento permitan formular recomendaciones tecnológicas. Esta últimas involucran diferentes aspectos del manejo de cultivo como el fertirriego y el control del microclima entre otros. Este laboratorio constituye un espacio muldisciplinario en el cual la industria 4.0 se integra con las ciencias y el diseño para incrementar la productividad agrícola disminuyendo el uso de recursos.